Thermal conductivity

& Thermoelectricity instruments

The thermal conductivity coefficient

is measured directly with

InoTherm®

Versatility in Thermal Conductivity measurements

- Measure the Thermal Conductivity Coefficient of solids, liquids, powders, and pastes with InoTherm

- A sample to measure is the size of a bean!

- Measure Thermoelectricity and Thermal Conductivity simultaneously with InoTherm-S

Cost-efficient thermal conductivity measurements

- Small samples

Measured samples are discs with diameters from 8mm and heights from 0.5 mm or similar volumes of liquid or paste.

- Artless sample preparation

No polishing is required; the sample faces non-parallelism of up to 5ᵒ is allowed.

- Short measuring time

The innovative quasi-steady-state approach allows a 7-minute measuring process with instant thermal conductivity and thermoelectricity calculations

Accurate thermal conductivity measurements

Experimental uncertainties for thermal conductivity coefficient not exceeding:

3% at k = 0.05 ÷ 1 W/m∙K,

2% at k = 5 ÷ 150 W/m∙K,

4% at k = 200 ÷ 500 W/m∙K.

Thermal conductivity meter electronic system stability: no Windows inside!

The thermal conductivity meter has a self-contained electronic system that operates the device and calculates the thermal conductivity coefficient and Seebeck coefficient. It does not depend on other hardware and software packages.

Thermal conductivity coefficient measurement principles

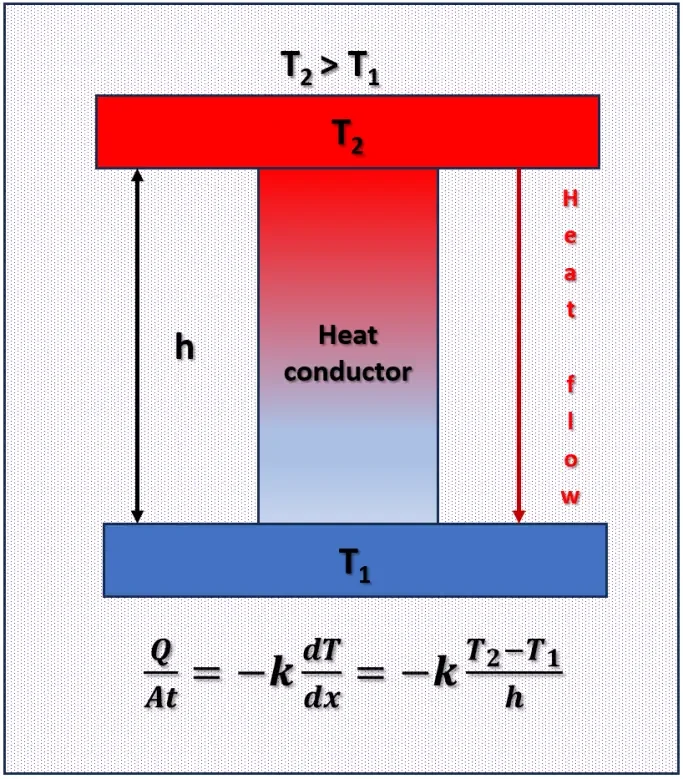

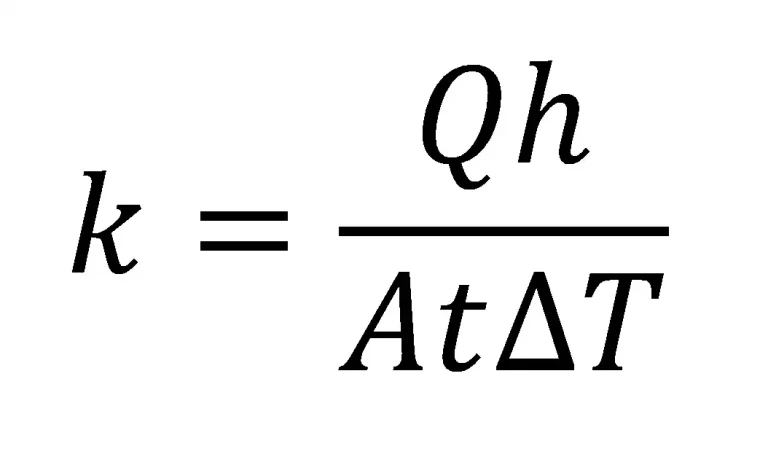

Thermal conductivity is the ability of materials to transfer thermal energy from a hot body to a cold one. Quantitatively, this ability is characterised by the thermal conductivity coefficient (k), which is the amount of heat passing through the sample of unit length and unit area if the temperature difference is 1 K. The thermal conductivity coefficient is expressed as W/(m·K).

Different thermal conductivity measuring methods can be based on steady-state or non-steady-state (transient) thermal processes. The steady-state instruments analyse the heat-transfer process presented in the picture. Therefore, they measure the thermal conductivity coefficient directly. The transient methods measure thermal diffusivity and then deduce the thermal conductivity.

During the stationary thermal conductivity process, the energy flux density is proportional to the temperature difference (see the picture). There: Q is the energy transferred through conductor thickness h during time t via the area A. The equation shows that the value of k can be obtained given the temperature difference and the amount of heat transferred via the sample with known geometry:

InoTherm

Thermal Conductivity Meter

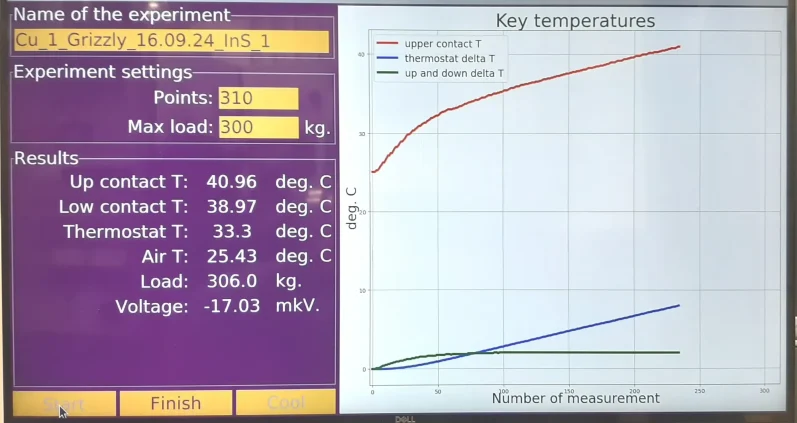

The raw data are presented on the screen during measurement and automatically collected into a data file. After data processing, the file also contains the thermal conductivity coefficient and the calculated error margins.

The instrument is factory-calibrated on standard samples and with all correction factors. The thermal conductivity measuring needs no other material parameters.

is a unique, new-generation thermal conductivity measuring device for quick, direct measurements of thermal conductivity coefficient. Initially designed for solids, it can also measure the thermal properties of gels, liquids, and powders.

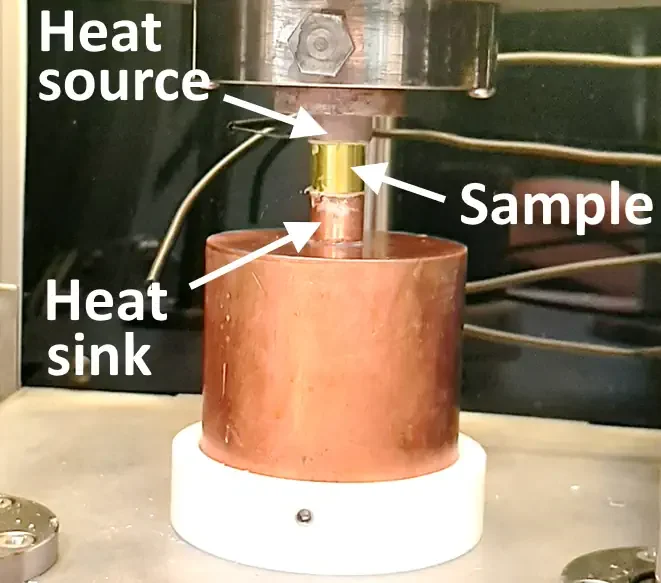

The system measures the thermal energy that transfers from the heat source via the measured sample to the heat sink attached to a heat accumulator. The temperatures of the sample faces, the accumulator, and the surrounding air are precisely measured. Therefore, the only additional data you will need to measure a thermal conductivity coefficient is the sample geometry.

Please, contact us to learn more about InoTherm

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.